Reducing NOx emissions is one of the main objectives of European environmental and transport policy. The EURO4 and EURO5 standards placed new demands on all involved industrial sectors, which have to be met since 2005 and 2008, respectively. To significantly reduce emissions, truck manufacturers and suppliers have developed the environmentally friendly SCR technology, among other things.

AdBlue, the trade name of the high-purity 32.5% aqueous urea solution (DIN 70070), is added to the hot exhaust gas stream, which contains the unwanted nitrogen oxides. With the help of the reducing agent ammonia, these are now converted into harmless nitrogen and water vapor in a catalytic converter. In this way, the pollutants in the exhaust gases of diesel-powered commercial vehicles are reduced by up to 80%.

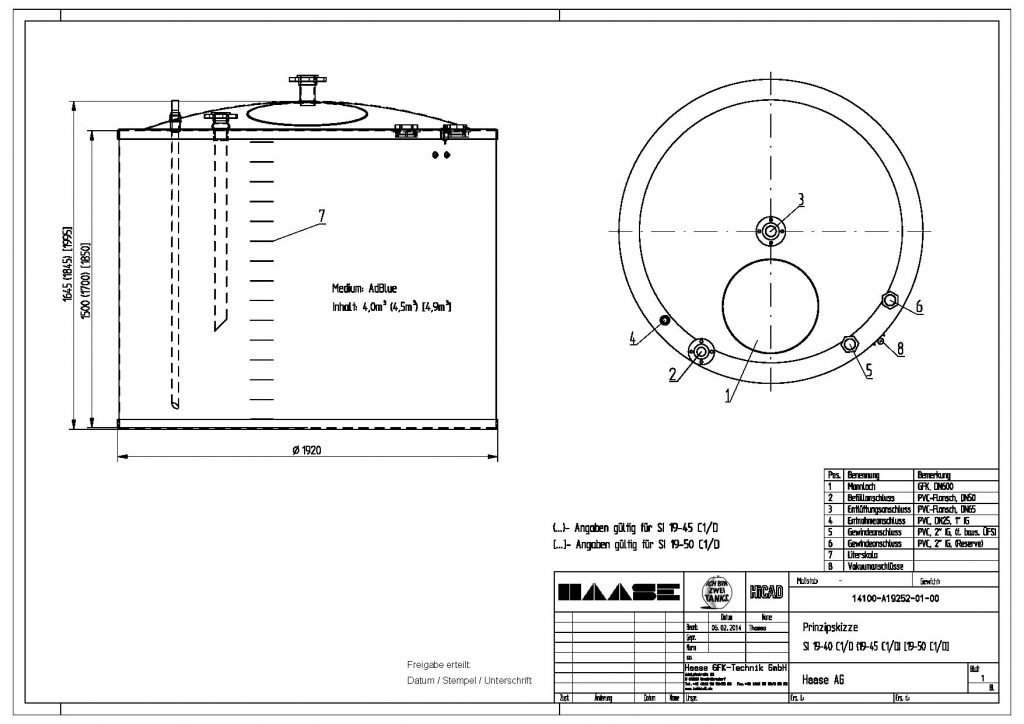

We recommend using Haase safety tanks to equip AdBlue filling stations. The on-site Haase flat-bottom tank can be used for above-ground storage.

The double-walled, cylindrical standing tank is made of age-resistant and corrosion-free glass fiber reinforced plastic (GRP) and does not require a sump. The tank is delivered in system parts and only assembled on site. This means that even large containers with a volume of up to 40,000 liters can be installed in the storage room. Thanks to the transparent tank wall, the fill level can be easily checked at any time.

The Haase spherical tank made of GRP is suitable for underground storage. Thanks to its three-wall structure, it is extremely stable and can be driven on with a corresponding manhole cover with up to 40 t.

Further information on the storage of AdBlue in our above and underground industrial tanks can be found here.