Light Liquid Separators

Light liquid separators are used to treat mineral oil-containing wastewater or as retention devices and thus prevent mineral oils from getting into drainage systems.

The Haase light liquid separators are characterized by their special container. Due to the combination of glass fiber reinforced plastic (GRP) and polymer concrete, the separators are permanently resistant to chemicals and can withstand high static loads.

THE APPLICATION AREAS OF THE LIGHT LIQUID SEPARATOR

Light liquid separators are prescribed in companies where large quantities of oil or petrol are stored or can escape, e.g.

GAS STATIONS

WASHING STATIONS

WORKSHOPS

PARKING AREAS

Further areas of application: scrap yards, car dealerships, transfer stations, freight forwarders, building yards, fire stations

THE ADVANTAGES

OF THE HAASE LIGHT LIQUID SEPARATOR

-

Resistance

dimensionally stable, corrosion-free and chemically permanently resistant thanks to the material GRP

-

Tightness

Dome shaft and pipe connections are factory-made on the tank, so there are no joints

-

Installation

also possible in cohesive clay soils and in groundwater, without complex substructure or foundation

-

Weight

Short installation times due to the low weight, enables moving without a heavy-duty crane

-

Entry

through the DN 1,000 manhole, without having to disassemble individual components

-

No follow-up costs

due to peeling coating or leaky joints in the shaft structure

-

Stability

Thanks to special polymer concrete, loads of up to 60 tons and inlet depths of over 4m can be achieved

-

Flexibility

Seamless dome shaft extension for realizing large installation depths and adjustable top section for variable adaptation to the top edge of the site

-

Compact

Sludge trap and coalescence separator are in one tank

-

Cleaning

due to the spherical shape, the separators have no edges on which dirt can stick

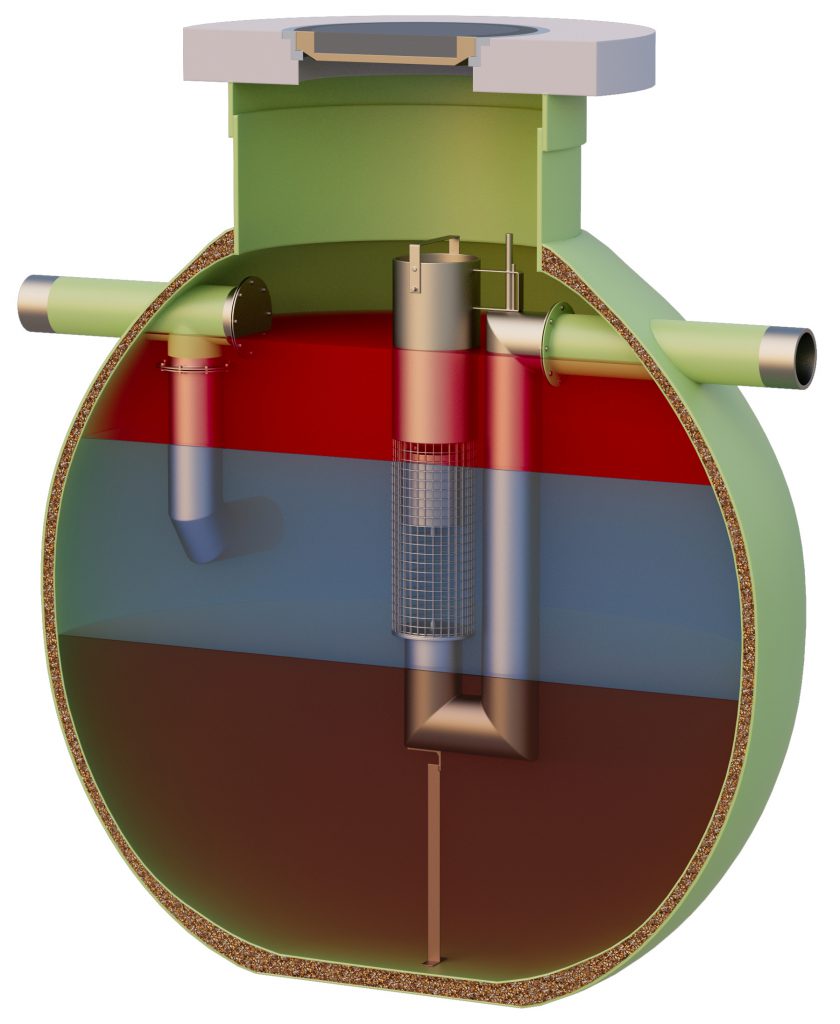

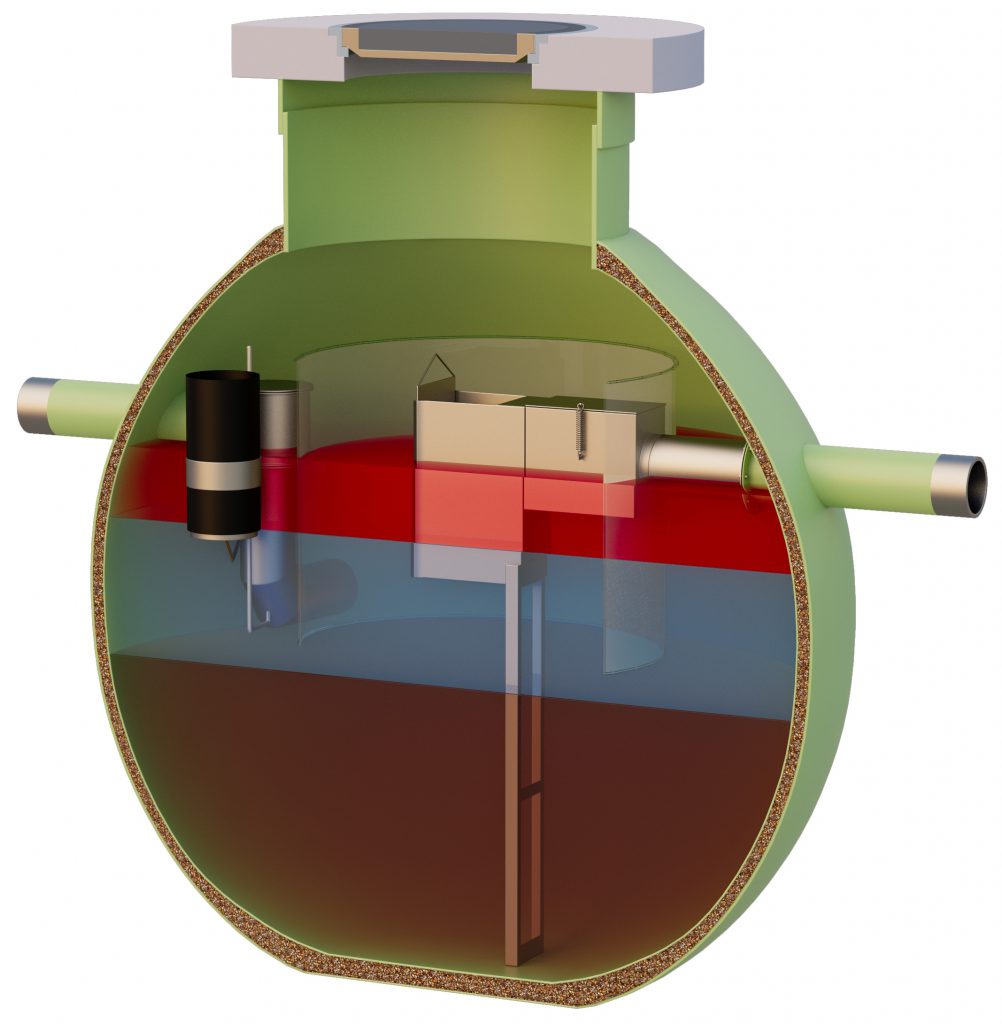

HOW OUR LIGHT LIQUID SEPARATORS WORK

Oil or gasoline separators (class II)

The class II separator separates the separable substances from the calmed waste water purely physically on the basis of the principle of gravity. Oil and petrol collect on the water surface due to their lower density, solids such as sand and mud sink to the bottom due to their specifically higher weight.

Coalescence separator (class I)

In the class I separator, the smallest drops of oil and petrol are brought together to form large droplets, which rise more easily and can therefore be retained better.

Automatic closure

The automatic closure consists of a float that has a higher density than oil but a lower density than water. The float is thus between the water surface and the separated light liquid and closes the separator when the maximum storage volume is reached.

Do you have any questions?

We will be happy to help you by phone or email.

info@haasetank.de

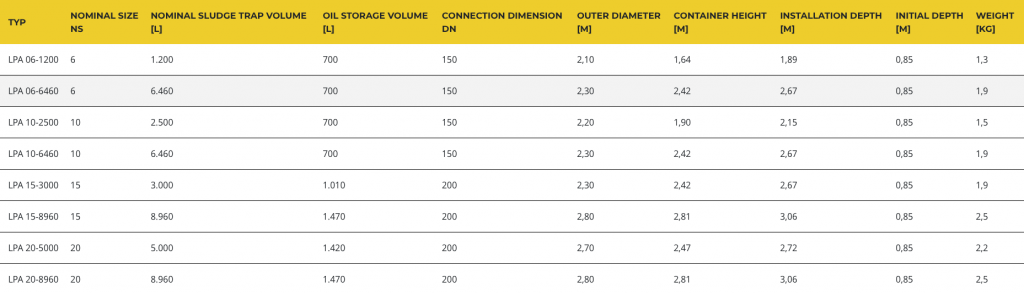

COMPARISON OF LIGHT LIQUID SEPARATORS

LPA WITH DRAIN CAP

-

Technology

Consistent cleaning performance and low-maintenance operation thanks to filterless coalescence up to NS15

-

Checking

Quick and easy without having to disassemble built-in parts

Coalescence separator (class I)

according to DIN EN 858-1 and DIN 1999-100 / 101

with general building inspectorate approval Z-54.3-537

Simple and robust for minimal effort

The LPA combines the sludge trap, coalescence separator and optionally the sampling point in one compact tank. The spherical shape of the container results in optimal flow guidance, which means that the coalescence insert up to nominal size 15 is filterless. This and the automatic closure on the drain, which is protected in the guide tube, reduces maintenance to a minimum. The clear structure and the easily accessible built-in parts make it easy for every operator and inspector to check the system.

Size Chart

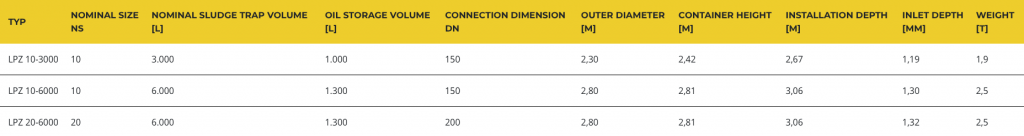

LPZ WITH INLET CLOSURE

-

Inlet closure

Mechanical safety against light liquid escaping without being raised

-

Gasoline and coalescence separators

Density-independent nominal size calculation

Gasoline and coalescence separators (class II – I)

according to DIN EN 858-1 and DIN 1999-100 / 101

with general building inspectorate approval Z-54.3-498

Effective and safe without the risk of jamming

The LPZ combines the sludge trap, petrol and coalescence separator and optionally the sampling point in one compact tank. The two separator classes II and I make it possible to reduce the nominal size by the density factor 1. In addition, the automatic closure at the inlet of the separator prevents the system from being backed up when the maximum oil storage capacity is reached, so that no light fluid can escape from the manhole cover if it continues to flow.

Size Chart

LIGHT LIQUID SEPARATOR EQUIPMENT

- liquid-tight dome shaft extension

- accessible and passable manhole covers

- Alarm system for oil layer thickness, accumulation and amount of sludge

- Leak detector for checking the tightness of the tank wall

- electrically conductive version with equipotential bonding

- Maintenance set for self-checking

QUALITY PAYS OFF!

Every joint has a weak point! Refurbishments are often not permanent and are also expensive. Concrete separators are delivered in individual parts (base body, ceiling slab / cone and manhole rings) and assembled on site – in contrast to separators made of glass fiber reinforced plastic.

THE HAASE SEPARATOR

… is a seamless unit thanks to the unique combination of the material GRP with the spherical shape. The dome shaft is laminated directly to the tank body in the production process and can be adjusted as required depending on the installation depth of the separator.

The Haase separator has a three-layer structure, and between the GRP walls there is a filling layer made of synthetic resin-bonded pebbles.

This construction ensures the permanent tightness of the container, both from the inside and from the outside. Thanks to this unique wall structure, the GRP separator combines the chemical resistance of plastic with the stability of concrete.

THE KEY TO SUCCESS

… are the operating costs running towards zero. With Haase separators, the entire three-layer structure is made of one type of resin, resulting in a compact unit.

Concrete, on the other hand, has to be protected by a coating or an inliner. However, coatings wear out over time and inliners are only introduced into the basic container, the shaft area usually remains unprotected. This results in renovation costs in the course of the operating years, which together with the purchase price significantly exceed the costs of a GRP separator.

THE LIGHT LIQUID SEPARATOR IN PRACTICE:

CONVINCE YOURSELF WITH OUR REFERENCES

Do you have any questions, would you like a specific offer or a free and non-binding on-site appointment? Then send us a message using our contact form or call your contact person Mr. Danilo Schlenz directly at +4935952 35515.