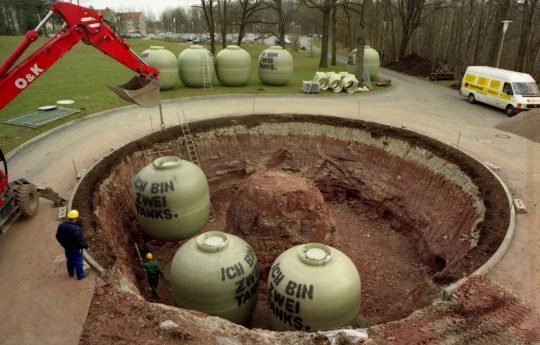

SPHERICAL TANK – UNDERGROUND STORAGE TANKS

There are high safety requirements for the storage of water-polluting liquids.

According to the provisions of the Water Resources Act (Section 19 WHG), water-polluting liquids may only be used in suitable and approved containers, e.g. in Haase’s double-walled spherical tank.

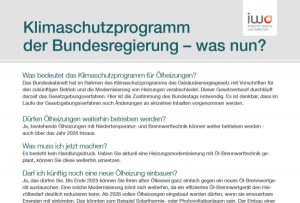

User of the Haase Spherical Tank

- Wastewater treatment plants

- Waterworks

- Utility companies

- Road maintenance

- Baths operations

- Landfills

- Laboratories

- (Company) gas stations

- Workshops

- Metalworker

- Recycling company

- Hospitals

- Data centers

- Hotels / Kitchens

- Breweries

- Agricultural holdings

- and many more: Users from industry, craft and municipalities

Media

- Sewage

- Precipitant

- Diesel fuel

- Urea / AdBlue

- Lubricating oils

- Coolants

- Refrigerant

- Firefighting foam

- Salt brine

- Food waste

- Swimming pool water

- Numerous acids and bases

Further media on request and according to media? list of the German Institute for Building Technology (DIBt), Berlin

THE ADVANTAGES

OF THE HAASE SPHERICAL TANK

-

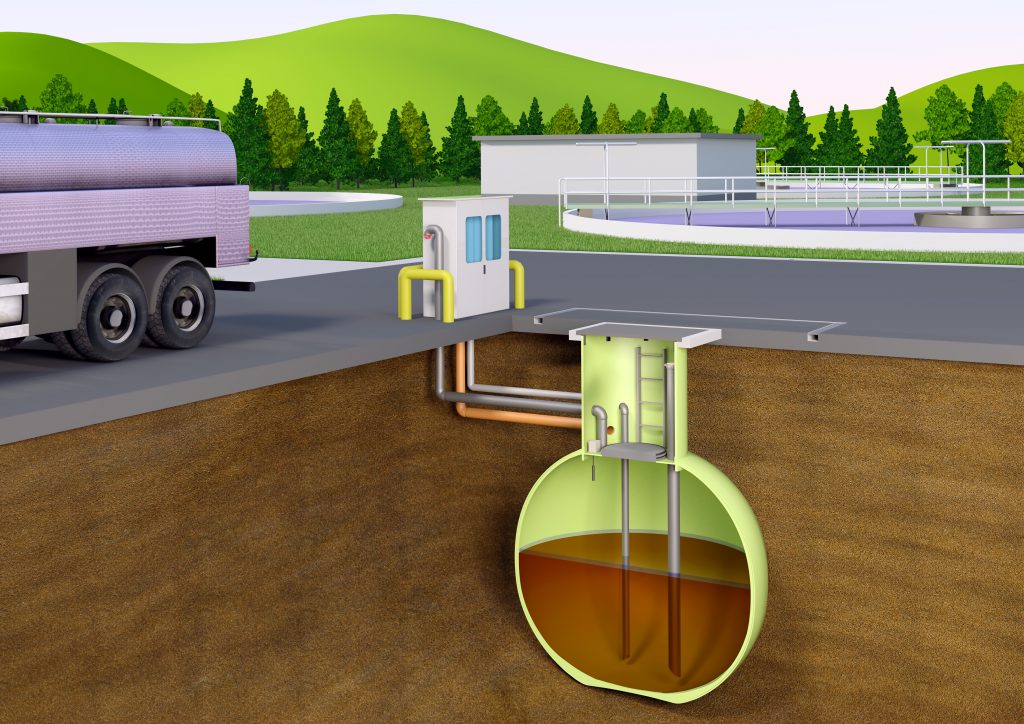

Safety

The tank is constructed with three walls: the outer and inner walls are each completely sealed and are constantly monitored with a leak detector.

-

Stability

The middle wall made of special poly-concrete ensures stability: therefore it can also be installed in the carriageway area (depending on the manhole cover).

-

Easy entry

The manhole ensures optimal conditions for maintenance or cleaning processes without having to remove existing fittings and connections.

-

Installation

The tank installation can be carried out completely by Haase at the customer’s request.

-

Resistance

By combining different types of resin and glass fiber, the durability of the GRP can be optimally adjusted to the respective storage medium (according to the media list of the DIBt).

-

Flexibility

The tanks are adapted to local conditions, individually equipped according to customer specifications and have the greatest possible flexibility in terms of type, number, dimension and arrangement of the connections and fittings.

-

Buoyancy control

In areas with high groundwater levels, the Haase spherical tank can be fitted with an optional buoyancy lock made of concrete.

-

Easy to clean

Because of the spherical shape, the underground tanks have no edges on which dirt can stick.

Double-Walled

Three-walled, spherical underground tank made of monitorable special poly-concrete with glass fiber reinforced plastic inner and outer wall. The walls are made of the same basic material and are connected to each other. The Haase underground tanks of the “Poly” series have the general technical approval Z-40.11-205 from the German Institute for Building Technology (DIBt) for the storage of heating oil EL according to DIN 51 603-1, diesel fuel according to DIN EN 590 and liquids according to media list 40 -2.1.1, 40-2.1.2 and 40-2.1.3.

OPTIONAL EQUIPMENT FOR THE SPHERICAL TANK

- Leak detector

- Overfill protection

- Level measurement

- Buoyancy control

- Manhole cover up to D 400

- Connections made of GRP, PVC, KG or metal

- Pipelines between the tanks

- Foot valves

- Shaft extension

- Shaft manager (entry aid)

- Antitheft

- Gelcoat

Do you have any questions?

We will be happy to help you by phone or email.

info@haasetank.de

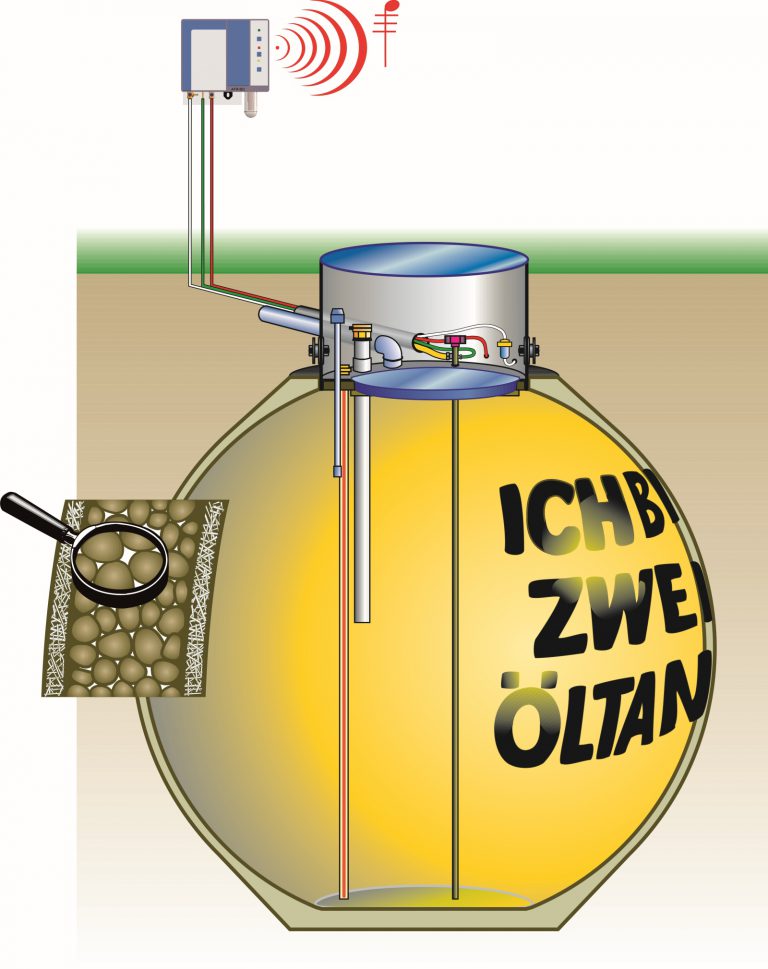

THE RIGHT TANK SIZE FOR YOUR NEEDS

Size Chart

SPHERICAL TANKS IN GRP

The Haase spherical tanks are resistant to a variety of chemicals and other storage media. Due to the multi-layer structure of the container made of polymer concrete, it is structurally highly resilient and still only has a relatively low weight. As a result, no heavy-duty crane is required for storage. Thanks to the material GRP, the containers are particularly durable and resistant to aging. The spherical shape enables easy cleaning of the tanks.

You can find more information on our GRP material and the various manufacturing processes on the following page.

THE SPHERICAL TANK IN PRACTICE:

CONVINCE YOURSELF WITH OUR REFERENCES

Do you have any questions, would you like a specific offer or a free and non-binding on-site appointment? Then send us a message using our contact form or call your contact person Mr. Sebastian Eggert directly at +4935952 35519.